Production quality,

our priority

Our expertise at the service of our customers

Thanks to our decades of experience, we are constantly improving our mastery of bar turning and machining.

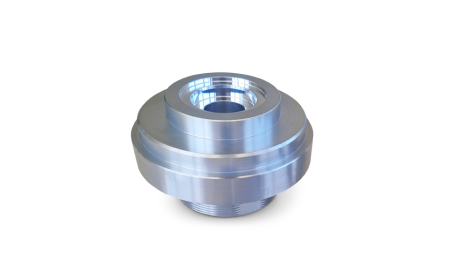

Our machined materials

Thanks to our multi-market culture and the diversity of our machinery, we machine free-cutting steel, stainless steel, steels suitable for heat treatment, and non-ferrous materials such as copper, aluminum and brass.

All our materials comply with RoHS and REACH (EC/1907/2006) regulations concerning the Registration, Evaluation, Authorization and Restriction of Chemicals, as well as regulations on minerals from conflict zones.

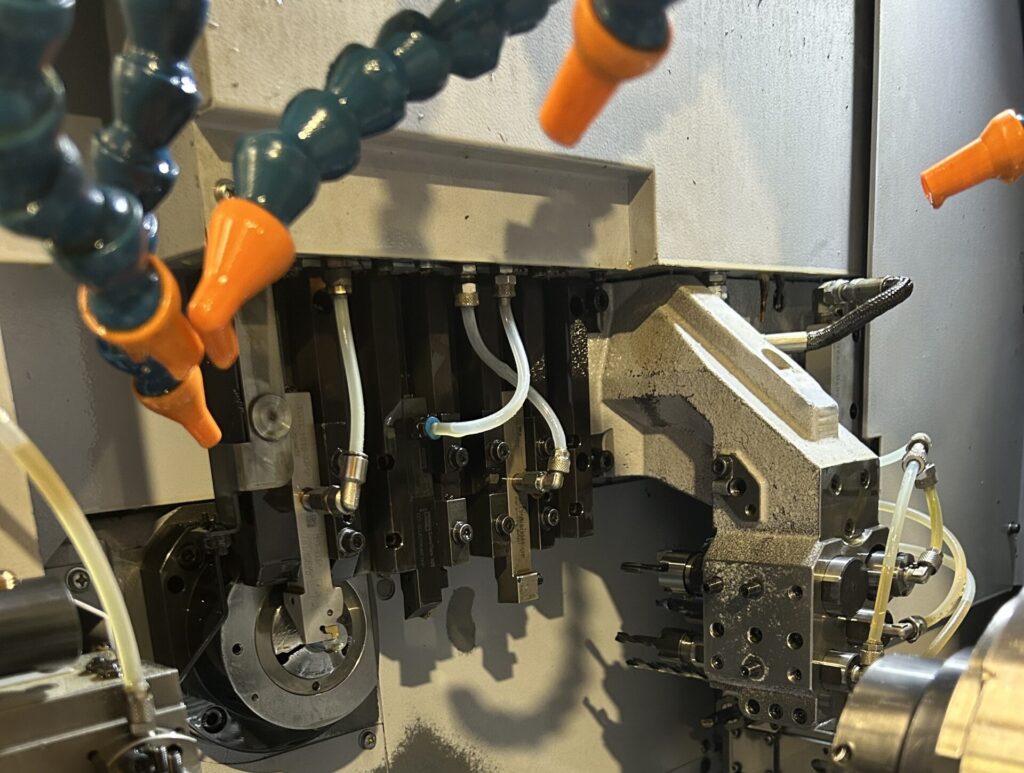

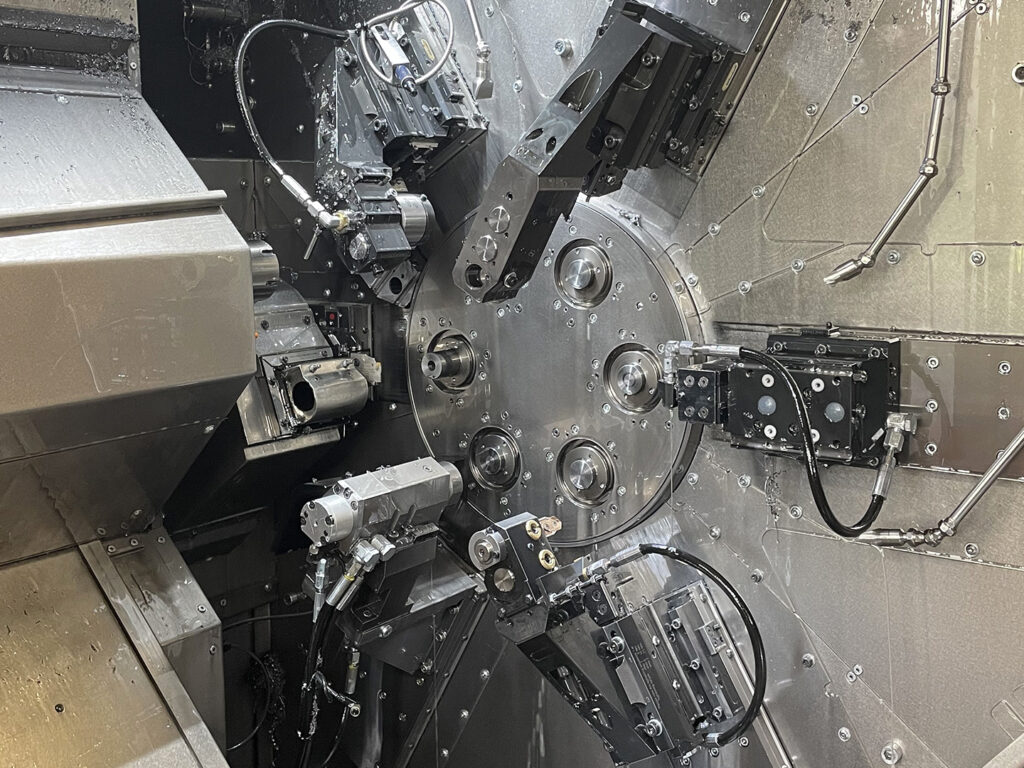

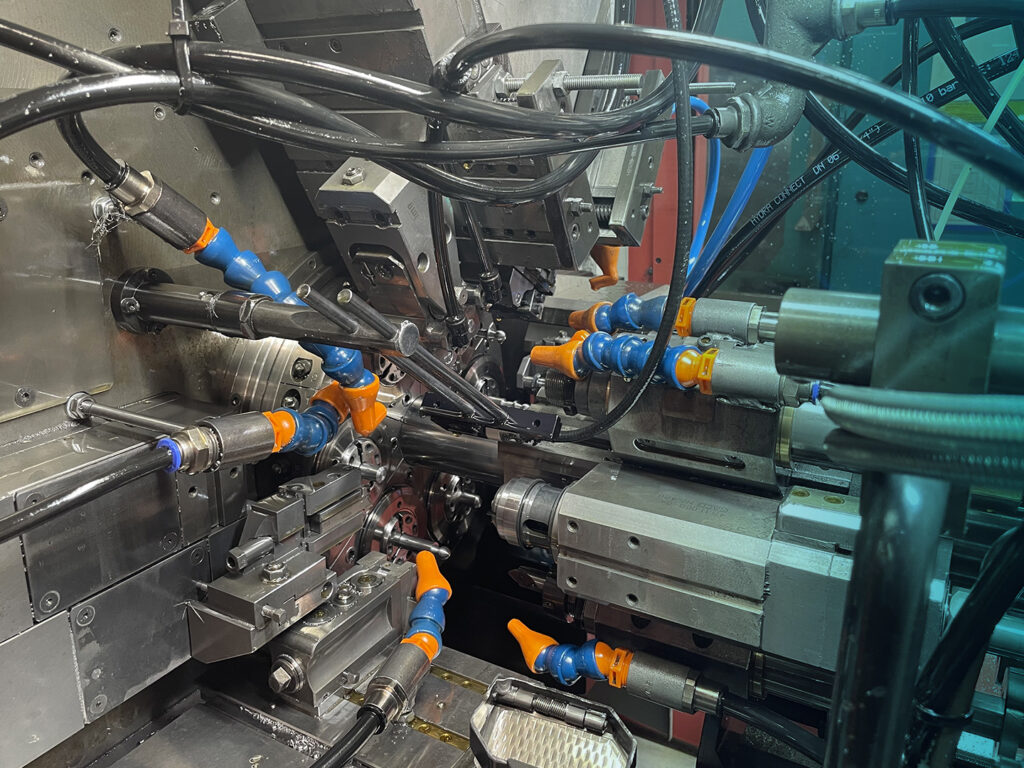

Our production facilities

Our well-maintained and regularly renewed machinery enables us to meet small, medium and large volume requirements and demanding deadlines.

- + Over 125 cam-operated and CNC multispindle lathes (max: 58 mm)

- 18+ single-spindle cam-type lathes (max: 32mm)

- + More than 115 CNC lathes in bar form (max: Ø80 mm) and chuck form (max: 25 kg)

- 10 horizontal and vertical machining centers

- 6 centerless grinders

- 2 high-frequency hardening units

- 2 robotized MIG welding cells

Made-to-measure precision

Our subcontractors

We benefit from a long-term network of subcontractors for surface and heat treatments.

Through long-term partnership contracts, we commit ourselves to ISO9001-certified service providers, and ensure consistent quality through regular audits.

Surface treatments :

- Zinc plating

- Nickel plating

- Phosphating

- Copper plating

- Silver plating

- Tinning

- Anodizing….

Heat treatment :

- Quenching and tempering

- Cementation

- Oxynitrocarburation …